that provides comprehensive support services for powder metallurgy manufacturing equipment, starting with foundational work.

units*1 of powder compacting /sizing press

and 259 units*2 of sintering furnaces.

*2 Data collected: Mar.1987-Mar.2021 (Including the older series)

#1 What is powder metallurgy?

01

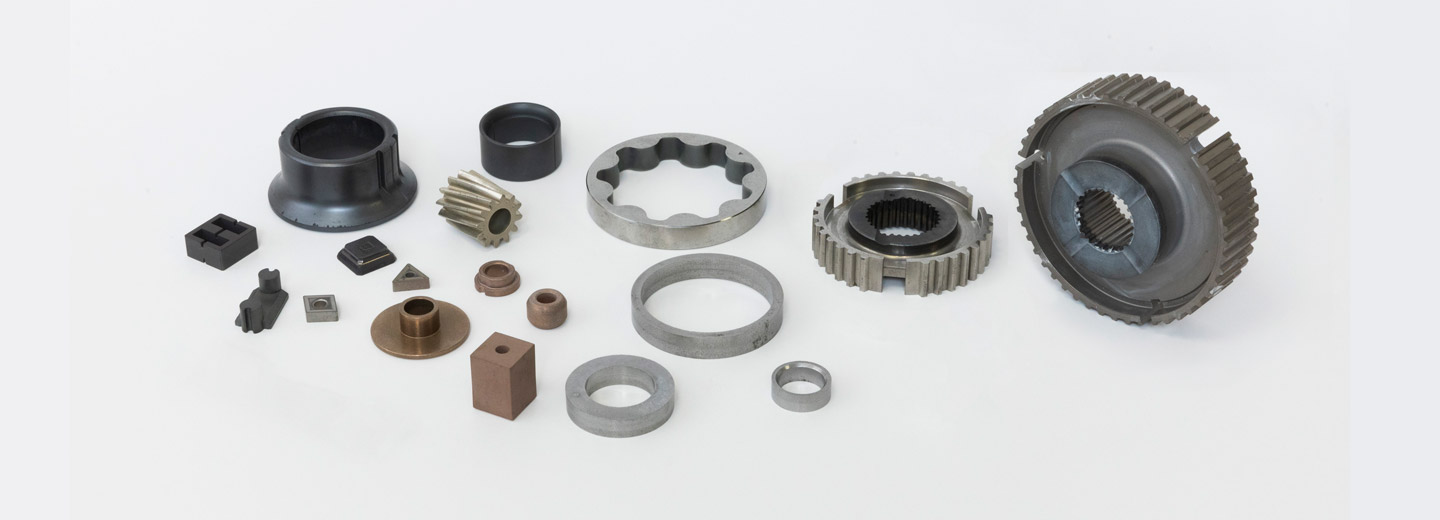

It is used for home appliances, car parts, industrial robots,

and parts of wearable

devices.

"Powder metallurgy" is one of the engineering methods used to manufacture products with a complex shape at high precision. Methods, such as casting, forging, cutting, and pressing are well-known, but powder metallurgy is known only by a limited number of professionals. The method is widely used for familiar home appliances, such as air conditioners and refrigerators, car parts, industrial robots, and the manufacture of parts of cutting-edge products, such as wearable devices including smartwatches.

02

Mixing a variety of metals and ceramics,

this method can mass-produce materials

with unique features.

"Powder metallurgy" is a process where raw material powders, such as metal powder and ceramic powder, are mixed and placed into a mold where they are subjected to high pressure to form a shape and high temperature to increase its strength. What's special about this method is that it can reduce the loss of materials and mass-produce complex products with high precision. It can create materials with unique characteristics by mixing powders of different substances to produce special features, such as wear and heat resistance, increased or decreased weight, and magnetism. If we were to say casting is "chocolate production (melting, cooling, and solidifying)," powder metallurgy would be seen as similar to "cookie production (mixing powder, forming it into a desirable shape, and baking it at an appropriate temperature)."

#2Product Introduction

"Powder compacting presses", "sintering furnaces", and "sizing presses" are essential for the basic powder

metallurgy process, and they are amongst the machines that we manufacture at Nagaoka Plant, our engineering

office in charge of industrial machinery and devices. Our Nagaoka Plant has 80 years of history and has long

received positive reviews from both domestic and international clients as the only equipment manufacturer in

Japan that provides basic powder metallurgy process services, including powder compacting, sintering, and

sizing.

In recent years, we have utilized our strong and reliable history and past achievements to provide

technologies that support next-generation plant operations, such as IoT, remote maintenance, and

energy-saving systems.

01 Powder compacting press

| Model | [S-] series | [IE-] series | [T-HS-] series |

|---|---|---|---|

| Product Image |  |

|

|

| Product Description | High-volume filling, Mid-low speed | Mid-volume filling, Mid speed | Low-volume filling, Mid-high speed |

|

|

|

|

| Maximum Pressure | 200kN-2,000kN | 30kN-600kN | 100kN-400kN |

| Filling Depth | 100mm-150mm | 40mm-60mm | 20mm-30mm |

| Number of strokes | 5spm-40spm | 8spm-60spm | 15spm-100spm |

| Model | [S-EX] series | [SX-] series | [SX-B] series |

|---|---|---|---|

| Product Image |  |

|

|

| Product Description | Parts of large vehicles | CNC Servo Press | CNC Servo Press |

|

|

|

|

| Maximum Pressure | 2,000kN-5,000kN | 100kN-800kN | 20kN-100kN |

| Filling Depth | 150mm | 80mm-120mm | 10mm-40mm |

| Number of strokes | 5spm-20spm | 8spm-25spm | 25spm |

02 Sintering furnace

| Model | Continuous Mesh Belt Furnaces [SCED-W] |

Continuous Mesh Belt Furnace [TSFG-W] |

Tray-pusher type High-temperature sintering furnace |

|---|---|---|---|

| Product Image |  |

|

|

| Product Description |

|

|

|

| Belt speed | 100mm-150mm/min. | 100 mm-150 mm/min. | - |

| Processing capacity | 100kg-450kg/hr. | 100 kg-300 kg/hr. | 30kg-90kg/hr. |

| Heat capacity | 71kW-280kW | 71 kW-177 kW | 100kW-210kW |

| Temperature |

|

|

|

| Atmospheric gasses | RX gas, AX gas, N2+H2 gas | RX gas, AX gas, N2+H2 gas | AX gas, N2+H2 gas |

03 Sizing press

| Model | [T-MS-] series |

|---|---|

| Product Image |  |

| Product Description |

|

| Maximum Pressure | 1,000kN-5,000kN |

| Maximum extracting power | 500-2,500kN |

| Number of strokes | 5spm-48spm |

#3 Our strengths

1

One-stop at our plant.

They are high-quality and reliable.

One-stop services, including design, procurement, construction, commissioning, and maintenance, are all conducted at our plant. Since we conduct and complete almost all the processes within our company, we can responsibly manufacture high-quality equipment and provide reliable support even after we deliver the products.

2

5000 units and operational knowledge succeeded from "TAMAGAWA".

We also provide retrofitting

services.

Succeeding the image of "TAMAGAWA", the traditional high-quality brand in powder metallurgy(*), we have

delivered a grand total of 4,887 units of power/straightening presses (data collected: Jan.1958-Mar.2021)

and 259 sintering furnaces (including older series) (data collected: Mar.1987-Mar.2021), giving us deep

experience and operational knowledge. We also provide retrofitting services to add functions or update the

clients' models, as well as repair and restoration services through overhauls. Many clients continue to

love our products through the Showa, Heisei, and Reiwa eras. Our master engineers are capable of updating

our services and products according to clients' technological advancement and keeping up with the changing

times to pass on the machines that have been loved by clients to the engineers of the next generation.

*Tamagawa Machinery Co., Ltd. merged with Mitsubishi Materials Techno in 2003.

3

We customize standard machines

depending on clients' needs.

The reason why we can make a

proposal for an entire produciton line is

because we are a complete engineering company.

We not only deliver equipment as it is but also customize and propose related equipment, according to requests of clients. "We want to add a dust collector to protect our workers' health," "we want to make the equipment IoT so we can collect data," and "we want to automate pickup and transfer processes for semi-completed products to save manpower" are examples of the requests we can handle. Our strength is that we have the adaptability and technology to reflect design ideas on our equipment and resolve clients' detailed concerns and requests. As a complete engineering company, we will try to resolve client concerns regarding the entire production line.

4

We have a number of overseas achievements.

The engineers of our company will visit you directly.

We have delivered various equipment to offices of Japanese companies located in China, the U.S., South Korea, Taiwan, Thailand, Indonesia, and other countries. Our engineers will visit the site and deliver the equipment according to the factory conditions in various countries and regions.

Through complete engineering,

we will support you with the manufacture of front and back equipment and help your factory become a

smart factory.

We can go deep into our clients' manufacturing sites and customize not only standard machines to meet

their needs, but also provide a complete service by providing industrial equipment that connects the front

and back of the equipment and handles semi-completed products.

We are constantly improving our technology to meet clients' various demands, such as IoT and product

traceability enhancement, so that our technology supports not only presses and sintering furnaces but also

the entire plant.

To those who are thinking of converting their factory to a smart factory, and those who are thinking they

need to work on labor saving, energy saving, IoT, and remote support first... Please feel free to consult

with us about even the most trivial problems you may wish to consult an engineering company about.

Powder feeding hopper exchanger

Hoppers can be exchanged by a conveyor system without using cranes, etc., so dangerous tasks handling heavy materials can be omitted.

Dust Collector

It collects powder that has overflowed around molds and powder that has settled around die sets. Not only does this help improve the working environment, it also helps maintain the product life of presses longer by avoiding equipment wear.

Automatic die set exchanger + Simulator

If you own several die sets, you can shorten the time needed to switch to the next die-casting mold and can improve the processing capacity.

Pickup Machine

They pick up molded products from presses and convey them to the next process. These machines are used together with presses to promote process automation.

Alignment Machine

They pick up molded products from presses and align them. These machines help with automation and manpower savings.

Palletizer

It automatically loads molded products on pallets and aligns them. The loading process tends to be a bottleneck, but this machine can save manpower.

Conveyors for compacted products (such as Automated Guided Vehicles (AGV))

It automatically conveys molded products, saving manpower.

Depalletizer

Compacted products will be automatically disassembled from the pallet and conveyed to the next process line. This can save manpower.

Exhaust Heat Recovery System

Aiming to save energy in sintering furnaces, we have adopted a thermal insulation structure, energy-saving heaters, thermal insulation paint, and introduced a temperature control system. With the introduction of the exhaust heat recovery system, the heat released from the furnace can be used for preheating the heating area to achieve further energy savings. (Amount of heat supplied: 20% reduction compared to our conventional furnaces.)

Unloading Equipment

A camera will be installed at the exit of sintering furnaces to automatically recognize and remove sintered products. The automation of transfer processes will be realized with this equipment.

Sintered product conveyors and set up machines

They automatically convey sintered products and set them up in a sizing press. They will help with automation and energy-saving.

Automatic die set exchanger + Simulator

If you own several die sets, you can shorten the time needed to switch to the next die-casting mold and can improve the processing capacity.

Pickup Machines

They pick up sintered products from presses and convey them to the next process. These machines are used together with presses to promote process automation.

Inspection Machine Booth

They check whether the sintered products meet the criteria and convey only the ones that passed them for delivery. They efficiently conduct inspection work and help save energy.

Tray Loading Robot

They automatically recognize sintered products to be shipped through cameras, and the robots will pack them into boxes, saving energy.

IoT* Data Collection Technologies

*Internet of Things

<This technology is expected to be used for the following purposes in the future>

・Reduce the burden of monitoring work. When equipment abnormalities are detected, early diagnosis will

be conducted based on this data.

・Conduct preventive maintenance based on accumulated data to reduce the losses caused by stopping the

operation of equipment.

*There are more possibilities we can expect with IoT, but overall, it will be useful for improving

processing capacities.

Equipment monitoring camera technology

<This technology is expected to be used for the following purposes in the future>

・Install them in various facilities and equipment, including presses and furnaces, and utilize the

recorded information for problem diagnosis.

・Accurately identify the cause of problems and handle them appropriately at the early stage to resolve

them as soon as possible.

Remote maintenance technology

<This technology is expected to be used for the following purposes in the future>

・In the event of trouble in the client's plant, conduct early diagnosis, maintenance, and remote

instructions in combination with IoT technology and equipment monitoring camera technology.

・Realize stable operations through preventive maintenance, early diagnosis, and early resolution.

#4 Company Information

- Company Name

- Mitsubishi Materials Techno Corporation

- Date Founded

- May 1958

- Capital

- 1,042.85 million Japanese Yen (100% of shares held by Mitsubishi Materials Corporation)

- Revenue

- 51,702 million Japanese Yen (as of March 2021)

48,451 million Japanese Yen (as of March 2022)

52,548 million Japanese Yen (as of March 2023) - Head Office

- 1-30-7 Taito, Taito-ku, Tokyo 110-0016, Japan

AKIHABARA i-MARK BUILDING - - Nagaoka Plant

- 2−4−1 Jooka, Nagaoka-shi, Niigata 940-8602, Japan

(1h35min. by bullet train from Tokyo Station + 10min. by taxi from Nagaoka Station) - - Our branch offices and engineering offices

- We have around 40 offices across Japan.

- Employees

- 988 employees (as of March 31, 2023)

- Our services

- Engineering and maintenance / Equipment manufacture / Surveys, analysis, assessment, countermeasure, and consultation regarding natural resources, geology, and environment

Request for information materials

Download documents

If you would like to learn about more detailed specifications,

you can download them here. (available

24/7)

Inquiries regarding

our products and services.

If you would like to request a quote or consultation on a specific matter, please use the contact form.