Accomplish 3,000 Construction Projects

Within 30 Days

Large Repairs of our client's Smelter and Refinery Conducted Once Every Two Years

Large Repairs of our client's Smelter and Refinery Conducted Once Every Two Years

Our client repairs their smelter and refinery once every two years. During the 30 days of the repair period, our client completely shut down the factory, including the furnaces. We check every single part of the factory, including those that cannot be checked during operating hours, such as furnaces, boilers, ore mixing machines, molds to form metals, turntables for transportation, blowers, etc.. 2,000 to 3,000 construction projects, from small ones to large ones, are conducted for this repair. It would be impossible to complete all of them within 30 days if they were not done simultaneously. The key is thoroughly planning to maximize the use of space, time, and labor forces. This needs to be conducted according to plan, and of course, without any accidents.

After disassembling a machine, we found that we would need to repair more than planned. Given that we cannot check the machine insides in detail for two years, this was no surprise. There are always things that can be noticed only if you stop operations to check the equipment. We are always prepared to deal with such “unexpected situations.”

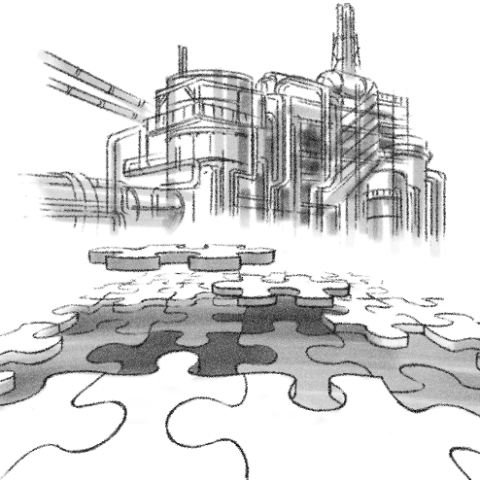

Construction will be performed according to a concise plan that removes unnecessary steps. Additional construction will be added to the plan with consideration for the schedule. Needless to say, it is essential to prepare the necessary components, labor forces, and equipment. As we continue the construction process, we always strive to do “more than the original plan.” Nevertheless, if the workload becomes too excessive, the quality of construction will decrease and safety will not be guaranteed. To find the perfect balance, we communicate with the client and partner companies to accomplish each task while managing the workspace, time, and labor forces. It is like finding the right combination of puzzle pieces scattered across the floor.

We manage each component and complete each task carefully but surely. When we handle heavy goods or work around moving vehicles, our workers are placed to ensure a secure and safe environment. The same can be said for the handling of tools. Some nuts are as big as a palm. Two workers are needed to fasten such nuts. The person holding a wrench and the person hammering need to collaborate effectively. Hammers can be longer than baseball bats. With such tools, even a small mistake can lead to a disaster. With human eyes, we check for danger. Check, check, and check again. There is no silver bullet that can prevent any disasters.

One month after the pause of factory operations, which happens once every two years, members become fully conscious in the silent premises. This is the feeling described as “being in the zone.” Accomplishing 2,000 to 3,000 construction projects within 30 or so days. Feeling reenergized, the factory begins its operation as the large repairs end. And the planning for two years later begins again.