Industrial Machinery

We handle everything, including proposals, design, manufacturing, installation, and maintenance, to make fully customized automated devices and lines specifically for our clients.

Beverages

We leverage our extensive experience in equipment for conveying empty cans and manufacturing aluminum cans to propose optimal conveying equipment and devices tailored to our clients' needs.

Air Flow Conveyors

This machine gently handles empty cans at high speeds without making scratches or dents by using air propulsion during the production process before adding the filling. It is capable of conveying 2,000 cans per minute.

Mechanical Conveyors

This is a conveyor that transports cans using top chains. We have achievements in various conveyance processes for both empty and filled cans. Our conveyors are known for their easy maintenance.

Single Filers

This machine gathers empty or full cans from multiple lines and conveys them in a single line. Our device is specially designed to relieve potential jams caused by bridges.

Vacuum Conveyors

This product uses suction on the bottom or top of empty cans to convey them during the can production process and before putting in the filling. This machine is used to convey cans vertically, convey cans near the front and back of inspection machines, and remove fallen cans.

Rinsers for Empty Cans

This is machine that sprays rinsing water into cans before putting in fillings and drains water. We have provided this machine to beverage production plants all over Japan.

Can Lid Folding Machines

The machine automatically counts the lids produced and packs them in bags befoer folding the bags flat and passing them to the palletizer. The processing capacity is 600 pieces per minute.

Can Lid Palletizer

During can lid production, this machine stacks sleeves of bagged can lids on pallets. The processing capacity is 1,200 pieces per minute.

Can Lids Guidance System

This machine guides can lids to the seamer without knocking them off at the beginning or end of the introduction process prior to filling.

DI Press for Aluminum Can Production

The 28-inch stroke enables high-speed forming at 300 spm, and the CIG ram-driving system makes it possible to form uniformly thick products.

Inside Spray Machine for Aluminum Can Production

Special coatings are applied to the outside and inside of cans using spray guns. The processing capacity is 250 cans per minute.

Necker Flanger for Aluminum Can Production

This is a necker flanger for multistages. The processing capacity is up to 1,800 cans per minute. We are able to manufacture a simple prototype version for trial.

Spin Flow Necker for Aluminum Can Production

This is a necker flanger designed to make a smooth neck. The processing capacity is up to 2,400 cans per minute.

Aluminum Can Inspector and Measurer

We have various equipment to inspect and measure aluminum cans during the can manufacturing and bottle can processes.

- Bottle can inspector: Inspects the shape of the outer and inner surfaces and neck of aluminum cans using image processing equipment.

- Light tester: Shines a light from the outside of cans and checks if there are pinholes on cans by transmittance.

- Automatic aluminum can measuring machine: Measures the shape and sizes of aluminum cans using image processing equipment.

- Enamel measuring machine: Measures the thickness of enamel coatings applied to the inner surface of aluminum cans.

Semiconductors

We provide high-quality pullers, which are essential for the manufacturing process of silicon wafers for semiconductors, and other related equipment.

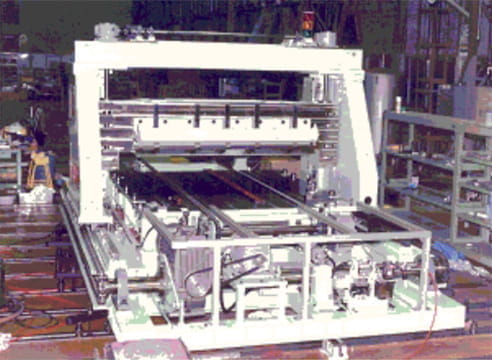

Polishing Pad Grooving Machine

This is a machine that grooves the surface of polishing pad sheets in any shape, such as radial lines, arcs, concentric circles, etc. It has very high precision and can groove newspapers, as well.

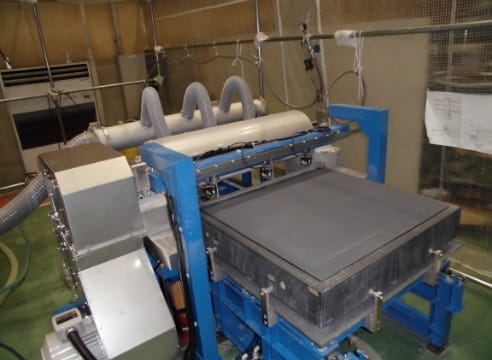

Polishing Pad Buffing Machine

This machine is used for polishing the surface of polishing pad sheets, etc. It can smooth various surfaces with high precision.

Sheet Buffing Machine

This is a machine to smooth out and make uniform the thickness of polishing pad sheets with high precision using our unique base slab and suction system.

Polishing Pad Slicer

This machine slices cake-shaped urethane foam polishing pad materials to a specified thickness. It can cut objects to a uniform thickness with high precision.

Automation and Laborsaving Technologies

We help clients improve efficiency of their production lines from the consideration stage. We propose optimal automation and laborsaving technologies.

Automated Assembly Lines, Between-Equipment Handling Equipment, etc.

If you are considering the automation of a production line, we are pleased to help you from the consideration stage. We will propose optimal plans for semi-automation or full-automation with a high degree of reliability.

Energy-Saving / Laborsaving Equipment

We realize systems with safety, maintainability, and consideration

of the environment while reducing manpower costs.

Also, We

can also propose designs that combine technologies (automatic

control technology that uses material handling technology,

equipment functional in a vacuum environment, robots, servomotors,

and image processing systems) or safety standard technology for

each safety category.