Technologies and Services

The Professional Engineers Essential for Plant Maintenance

We have approximately 400 engineers specializing in plant

maintenance. To be able to handle various matters that occur at

clients' plants, our engineers specializing in machinery,

electricity and control, civil engineering and construction, and

chemistry are always stationed at our engineering offices across

Japan and provide technologies depending on clients' needs.

Valuing close communications between our plant maintenance

division and related organizations, we are working on a cycle

where technologies developed in maintenance work are used in

engineering and technologies developed through engineering work

are used in maintenance. At our company, we value this cycle to

realize the continuous improvement of technologies in the

engineering field ("plant creation") and in the maintenance

field("plant protection"), and we consider this crucial to keep

supporting our clients' plants.

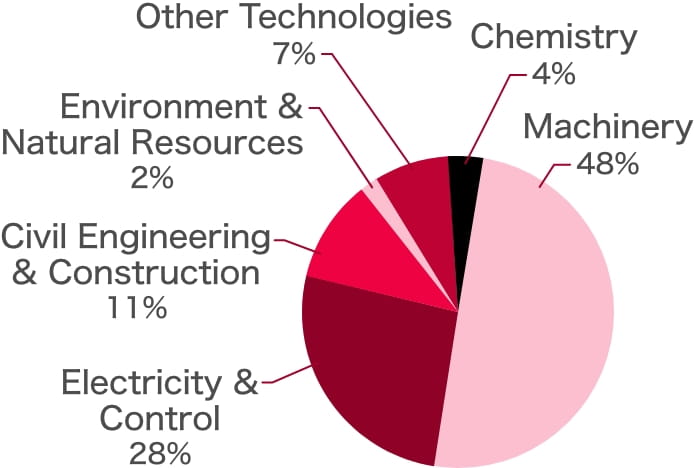

Ratio of plant maintenance engineers in terms of specializations

We have 48% of maintenance engineers in machinery, 28% in electricity and control, 11% in civil engineering and construction, and 4% in chemistry. Utilizing technologies in each specialization forconstruction of new plants and expansion and enhancement of existing ones, we handle everything, including design, construction, and aftercare.

Major Licenses in Specializations

Machinery

First-Class Plumbing Work Operation and Management Engineer, Managing Engineer (09 Plumbing), Managing Engineer (20 Machinery Installation), First-Class Machine Maintenance Engineer (01 Machine Maintenance), First-Class Machine Maintenance Engineer (03 Equipment Inspection), Safety Sub-Assessor

Electricity and Control

First-Class Electric Work Operation and Management Engineer, Managing Engineer (08 Electric), Managing Engineer (22 Telecommunication), First-Class Machine Maintenance Engineer (02 Electrical Maintenance), First-Class Electrical Work Engineer, Second-Class Electrical Work Engineer

Civil Engineering and Construction

First-Class Civil Engineering Work Operation and Management Engineer, First-Class Building Operation and Management Engineer, Managing Engineer (01 Civil Engineering), Managing Engineer (02 Building), Managing Engineer (13 Paving), Managing Engineer (25 Doors), First-Class Architect, Second-Class Architect

Click here for other licenses and the number of license holders >

Our service areas

We provide various services that are essential for the stable operation of clients' plants.

Mechanical Engineering

The maintenance of machinery and equipment is a very important

factor for the stable operation of plants.

We support our clients' plants by offering technology services

depending on their needs, including various designs, manufacture,

maintenance, piping, installation, and inspection.

Machinery Design

- Preliminary survey (field survey, inquiries to government offices, preliminary meetings)

- Layout map, production drawing of tanks and heat exchangers (including pressure vessels), stand and work platform drawing, piping drawing

- Strength calculation of tanks and heat exchangers, energy loss calculation for pipes and ducts, thermal stress calculation

- Compliance with standards and laws (JIS, Fire Service Act, Construction Code for Pressure Vessels, High Pressure Gas Safety Act, etc.)

Equipment Manufacture

- Tank production (materials: SS, SUS, Hastelloy, Inconel®, titanium)

- Tank production (materials: PVC, FRP, FRP+ Lining (PFA, PVDF, PP), etc.)

- Heat exchanger production (materials: SS, SUS, etc.)

Equipment Maintenance

Various pumps, blower disassembly and maintenance, reducer maintenance, hydraulic cylinders, tank and heat exchanger (including pressure vessels) maintenance, various tank repairs, overhead crane inspection and maintenance, transfer conveyor chain maintenance, bucket elevator rail and chain maintenance, bag filter cloth and retainer maintenance, various equipment rubber lining and FRP repairs, polishing equipment maintenance, vacuum pump maintenance, replacement of sintering furnace insulations, filter press maintenance, power press and sintering furnace maintenance

Pipe and Duct Installation

- Piping work (Types: SGP, STPG, SUS, sanitary pipes, copper pipes, lining steel pipes, etc.)

- Piping work (Types: PVC, PE, PP, FRP, PVDF, etc.)

- Duct work (Materials: hot-dip zinc-coated steel sheets, SS, SUS, FRP, etc.)

Installation Work

Cooling towers, gas coolers, chillers, heat exchangers, evaporators, drying towers, bag filters, Cottrell precipitators, convertors, absorption towers, scrubbers, washers, pumps, blowers, tanks, compressors, vertical drawing machines, polishers, processors, crushers, grinders, absorption towers, conveyors, non-steel materials sorting machines, power presses, sintering furnaces

Equipment Inspection

- Performance Inspection (boilers and type-1 pressure vessels)

- Pipeline pressure resistance test, pipeline airtightness test

- Ultrasonic thickness gauges, PT (Liquid Penetrant Testing), UT (Ultrasonic Testing, Water Immersion UT Testing), RT (Radiographic testing, Digital RT Testing), ET (Electromagnetic Testing)

- Material analysis, Vibration easurement

Electrical and Control

In a wide range of our maintenance support, including construction work support, maintenance, reforms, and repairs, we create stable plant operations with proposals that take into account economic efficiency and maintainability and provide electrical, instrumentation, and control technology services to help clients achieve a safer and more comfortable work environment.

Design, construction, maintenance, and repair of ancillary equipment

- Electrical equipment in buildings (electric light, power, and air conditioning)

- Fire prevention facility (automatic fire alarm system)

- Phones and broadcasting facilities

- Telecommunication equipment, alarms, and other low-voltage electrical equipment

Design, construction, maintenance, inspection, repair, and renewal of power receiving and transforming facilities

- Super-high-voltage substation

- High-voltage-power receiving and transforming facilities

- Power factor improvement

- Renewable energy related facilities

Electrical, instrumentation, and control design, installation, and maintenance of plants, machinery, and ancillary facilities

- Various plants (chemical, manufacturing, assembly line plant, etc.)

- Machinery

- Monitoring and alarm systems

- Environmental (wastewater treatment, exhaust gas treatment, etc.)

Maintenance and improvement of equipment safety and productivity

- Various proposals for equipment safety improvement (e.g. proposal to introduce additional safety devices)

- Proposals for various controls to maintain and improve the performance of production equipment

Renewal Proposals

- Advancement and increasing speed of control equipment and information and communication equipment

- Renewal of control equipment for which the manufacturer's maintenance service has ended

- Telecommunication network

Control system engineering and maintenance support

- Power control panel design and manufacture

- Design and manufacture of monitoring (alarm) control panels

- Structuring and maintenance of a decentralized control system that has each control panel as a subordinate.

Civil Engineering and Building

We provide integrated services from planning, design, construction, and maintenance for all civil engineering structures in factories, including factory buildings, offices, hazardous material facilities, exterior structures, infrastructure facilities, and other factory-related facilities, as well as ancillary factory structures, including equipment foundations and stands, ventilation and air conditioning, plumbing system, and clean rooms.

Civil Engineering Design

- Preliminary survey (field survey, inquiries to government offices, preliminary meetings)

- Plant design (non-ferrous metals, semiconductors, precision machinery, food, wastewater treatment, research facilities, power plants, etc.)

- ・Plant-related facility design (hazardous materials facilities, offices, welfare facilities, exterior structures, infrastructure facilities on site, etc.)

- Structural consideration and calculations for existing buildings (for equipment production increase, installation of solar panels, etc.)

Comprehensive civil engineering and building construction

- Plant construction (new, expansion)

- Plant-related facility construction (new, expansion)

- Plant civil engineering construction (site development, infrastructure facilities on site, exterior structures, green planting work)

Civil engineering renovation and repair work

- Reform and repair work of existing buildings, emergency construction (civil, mechanical, electrical, air conditioning, and plumbing engineers will propose a comprehensive plan.)

- ・Demolition of existing buildings

- Maintenance and inspection of civil engineering structures (survey - construction, proposals for preventive maintenance, etc.)

- Heat control by whole or individual air conditioning system, installation of clean rooms, etc.

Design and construction of plant ancillary structures

-

Design and construction of plant ancillary structures

(foundations of various mechanical and electrical equipment, wastewater treatment equipment, equipment stands and piping and wiring racks, etc.)

Compliance surveys (with laws and regulations) and legalization work

- Preliminary survey (field survey, inquiries to government offices, preliminary meetings)

- ・Various legal checks (consultation about civil engineering-related laws, including Building Standards Act, Fire Service Act, Factory Siting Regulatory Act, etc.)

- Reporting, planning, and construction proposals for legal compliance

Earthquake-resistant design check and reinforcement construction

- Preliminary survey (field survey, design confirmation, preliminary meetings)

- Earthquake-resistant design check and reinforcement design creation

- Earthquake-resistance reinforcement construction (comprehensive proposals including architectural, electrical, and facility construction related to the reinforcement)

Process Engineering

Our main focus is providing technology services for process design assistance in new Mitsubishi Materials Group project plans and commissioning services for relevant construction projects. We also handle basic designs, technology proposals, and operational support for various in-house process calculations and material support.

Process Design

- Creation of process flow and material balance

- Layout planning

- Equipment data sheet creation

- Pipe sizing, P&ID creation

Wastewater treatment technology

- Through mining wastewater treatment projects, we have acquired the necessary technologies and know-how.

- Our preferred treatment method adds an alkalinizing agent to wastewater containing heavy metals to adjust the pH level, which solidifies the water's heavy metals in an ionic state for sedimentation and separation. Once the concentration of heavy metals in the water is reduced to below the effluent standard value, the water will be discharged.

Technology Proposals

- Investigation, consideration, and planning for inquiries (questions and problems) regarding reaction processes and chemical properties.

- Market research and feasibility studies on equipment for new business plans and proposals for concrete implementation.